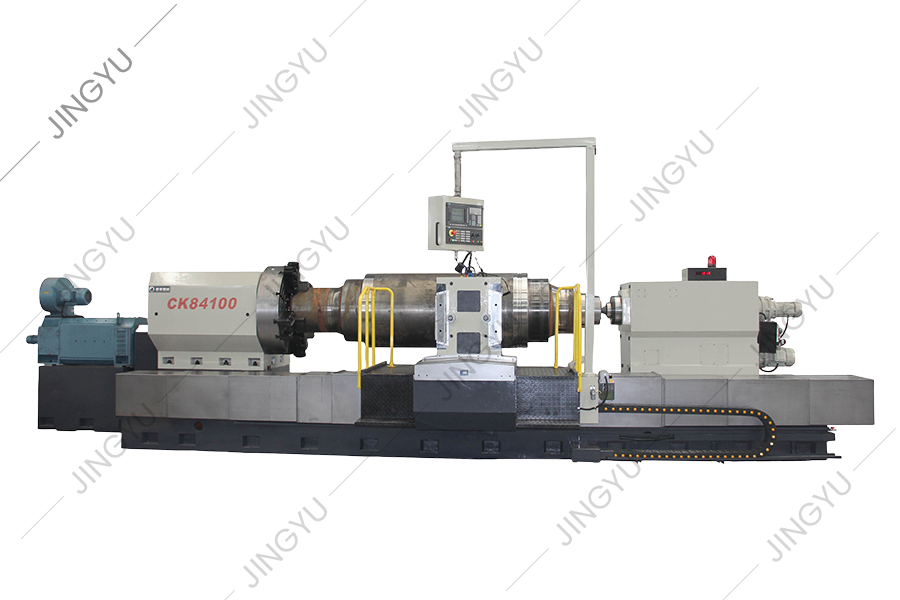

Ck84100

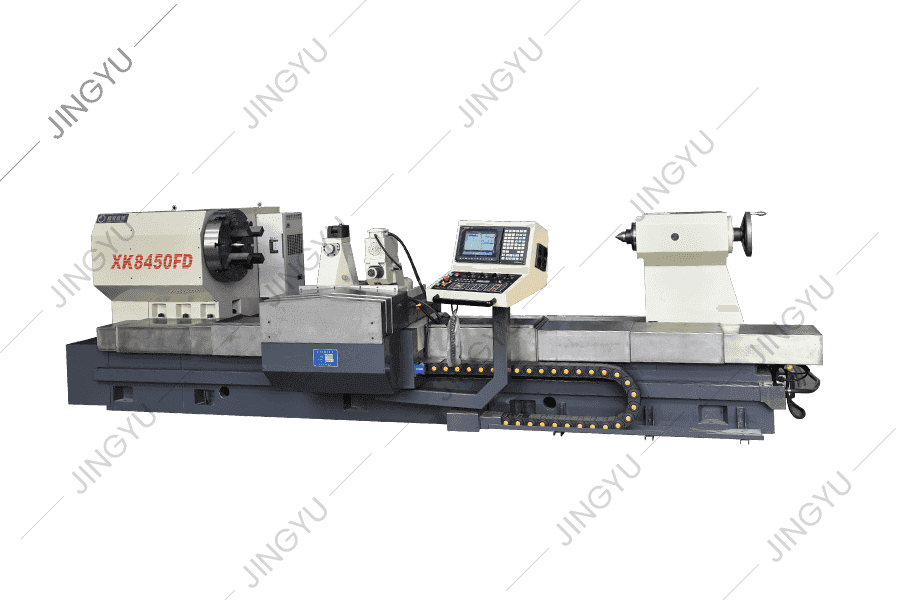

●The CK84100 CNC roll lathe bed adopts the overall 4 1 guide rail structure, that is, the bed's horizontal arrangement of four rectangular rails to provide the movement and positioning of the saddle and tailstock, and set up an auxiliary rail on the vertical surface of the front side of the bed for the saddle auxiliary support, so as to ensure that the saddle, the tool holder has a better rigidity, and can bear A maius secans torque.

The reference guide rail of the bed adopts the overall super-audio quenching, and the matching surface is affixed with an imported guideway soft belt to ensure the micro-wear movement of each feed component, and maintain high precision and high stability for a long time. Quidam altitudo differentia est disposito inter Sternas et Tailstock Rail ut eu et coolant non invadendi stercere.

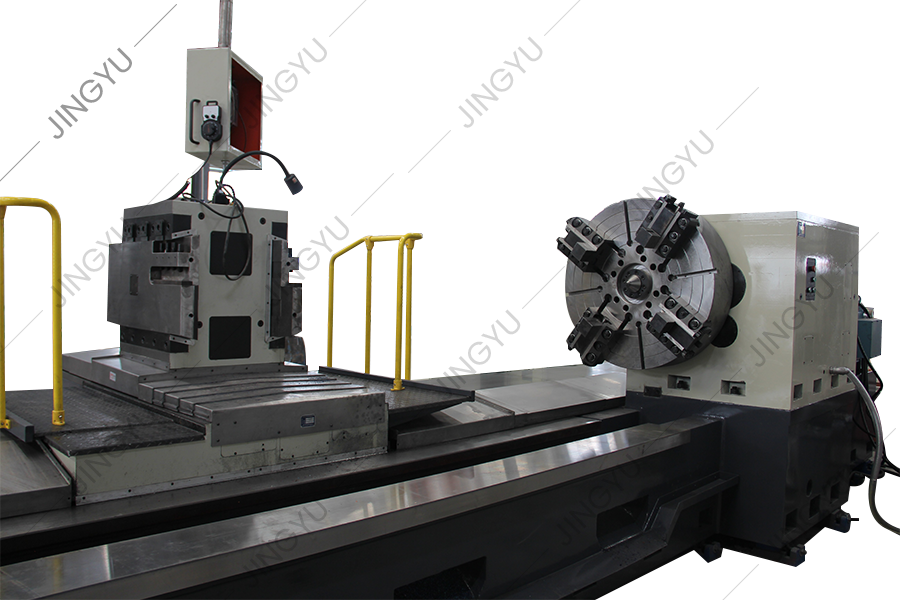

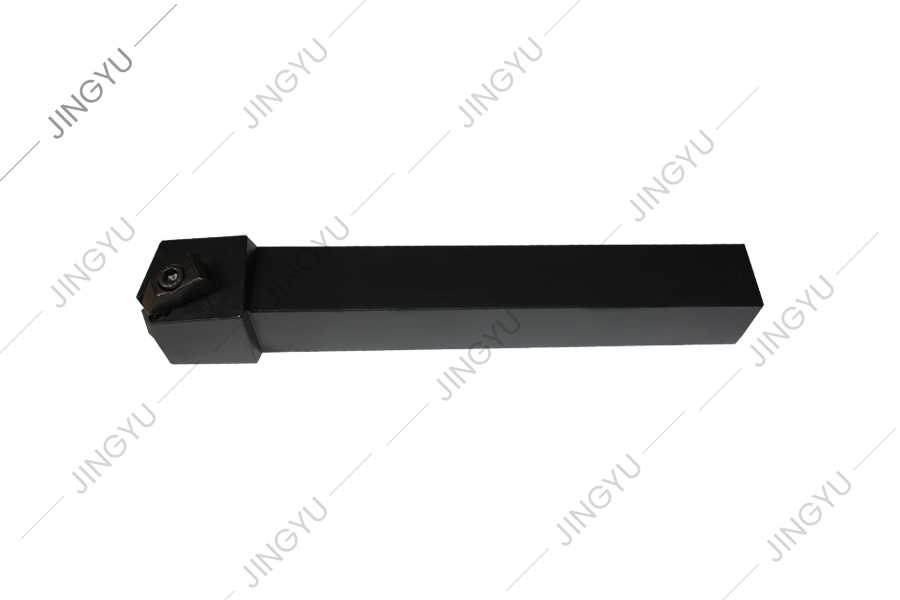

● Sternite instrumentum Holder adoptat an ao-type integralis tool possessor consilium. In tool possessor can amplio rigiditate ad instrumentum possessor et redigendum vibrationem per conversus ex machina instrumentum. Et adjusting positio ad instrumentum requiem laminam ad aptet ad altum sulcus transitum volumine processus. Reducere defectum rigorem per extensionem ad instrumentum tractare, ut instrumentum tractare resonatur, afficiens sectandi perficientur.

Nostrum Company potest etiam eligere ad configurare cnc Tool possessor secundum ad Lorem scriptor requisitis (id est suadetur quod angulus ferro users eligere).

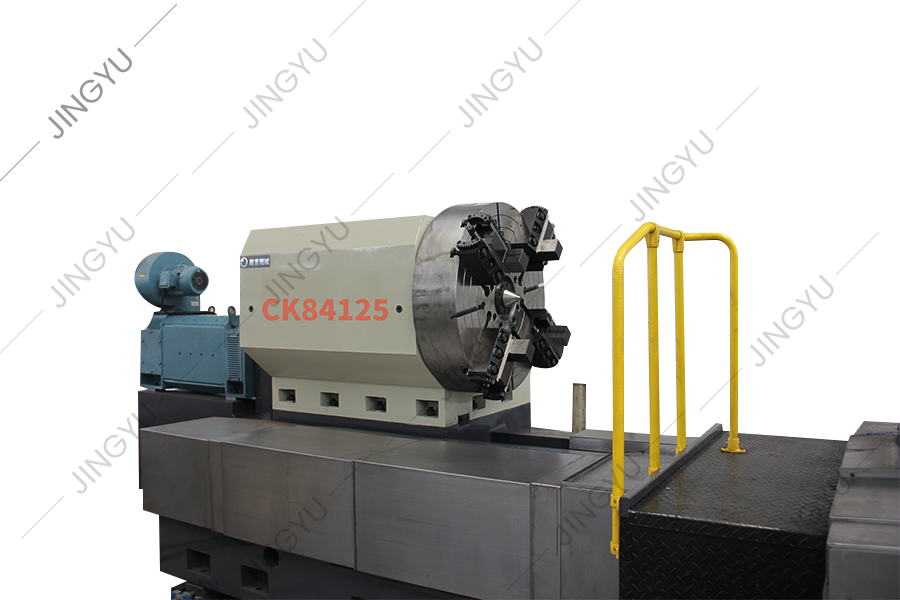

Ck84125

● Lathe headstock adoptat confirmat geminus murus arca structuram; Et pelagus hastile adoptat formam duo-punctum auxilium, rationabile afferentem configuratione, et span consilio, pelagus hastile est princeps rigiditatem et afferentem capacitatem. Optimized transmissione ratio omnis pulsus per VI gradu praecisione calces cum excelsum frequency extinxit et stridor ut headstock habet characteres humilis strepitu, princeps transmissione accuratas et magna output torque.

Pelagus hypae traductionem adoptat hydrau automatic subcinctus II calces subcinctus & DC celeritate ordinacione motor coegi stollens celeritate ordinacione ratio ut machina fusum habet amplis 1-200rpm, princeps dynamic est a wide regulantur range.

Et dorso de headstock est disposito cum puga statione, quae potest control operationem de fusum, ut positivum et negative rotationis et subitis subsisto.

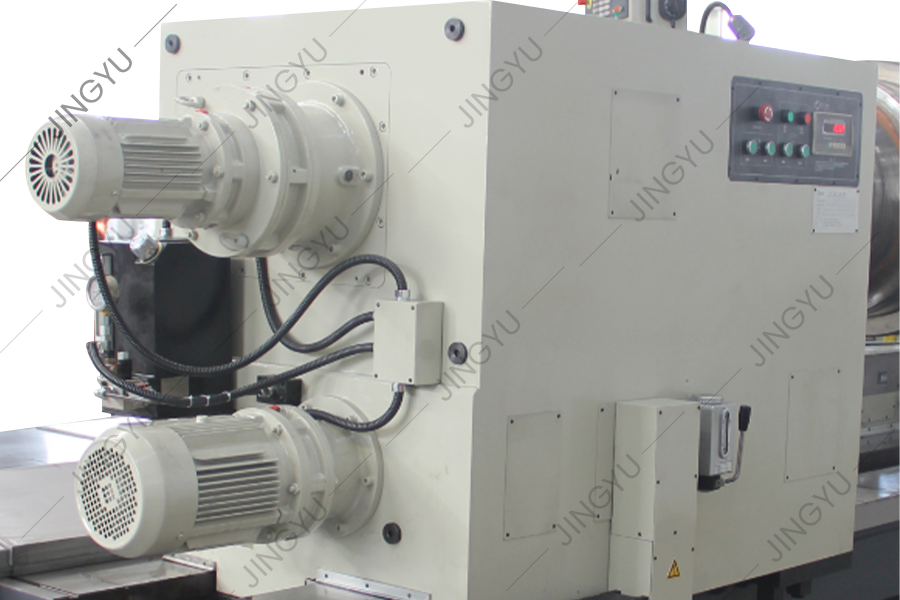

● in tailstock adoptat a structural consilium de independens rotating fusum & axial telescopic temperatio in Tailstock Sleeve. Tailstock Fusum taper foraminis est 100-1: V. Tailstock corpus induit integralis structuram, quod excludit incommoda inconstabili accurate, pauper onus-afferentem capacitatem, et pauperes causat a traditional superioris et inferioris split.

In tailstock machina instrumentum instructum est summus perficientur pressura sensorem, quod adhibetur ad occasum, mensurae, et feedback in tailstock claruping vi cum torno fibulis workpiece. Per occasum et adjusting in operating pressura sentire moderatoris, tensis vis de tailstock tip in workpiece potest esse automatically imperium et proponendum. Et laxitas et clamping de tailstock sleeve sunt statim intellexit per hydrau imperium ratio.

A workpiece scelerisque deformatio ultricies mechanism est disposito in tailstock sleeve. Axial longitudo mutatio in workpiece in operationem machinae instrumentum absorbetur et compensatur per disco vere in sleeve.